Understanding the Basics: Resin and FDM Printing

3D printing encompasses a variety of technologies, among which resin and Fused Deposition Modeling (FDM) stand as widely used methods, each with its unique characteristics and processes. Understanding how these two printing techniques operate is essential for evaluating which is better for creating miniatures.

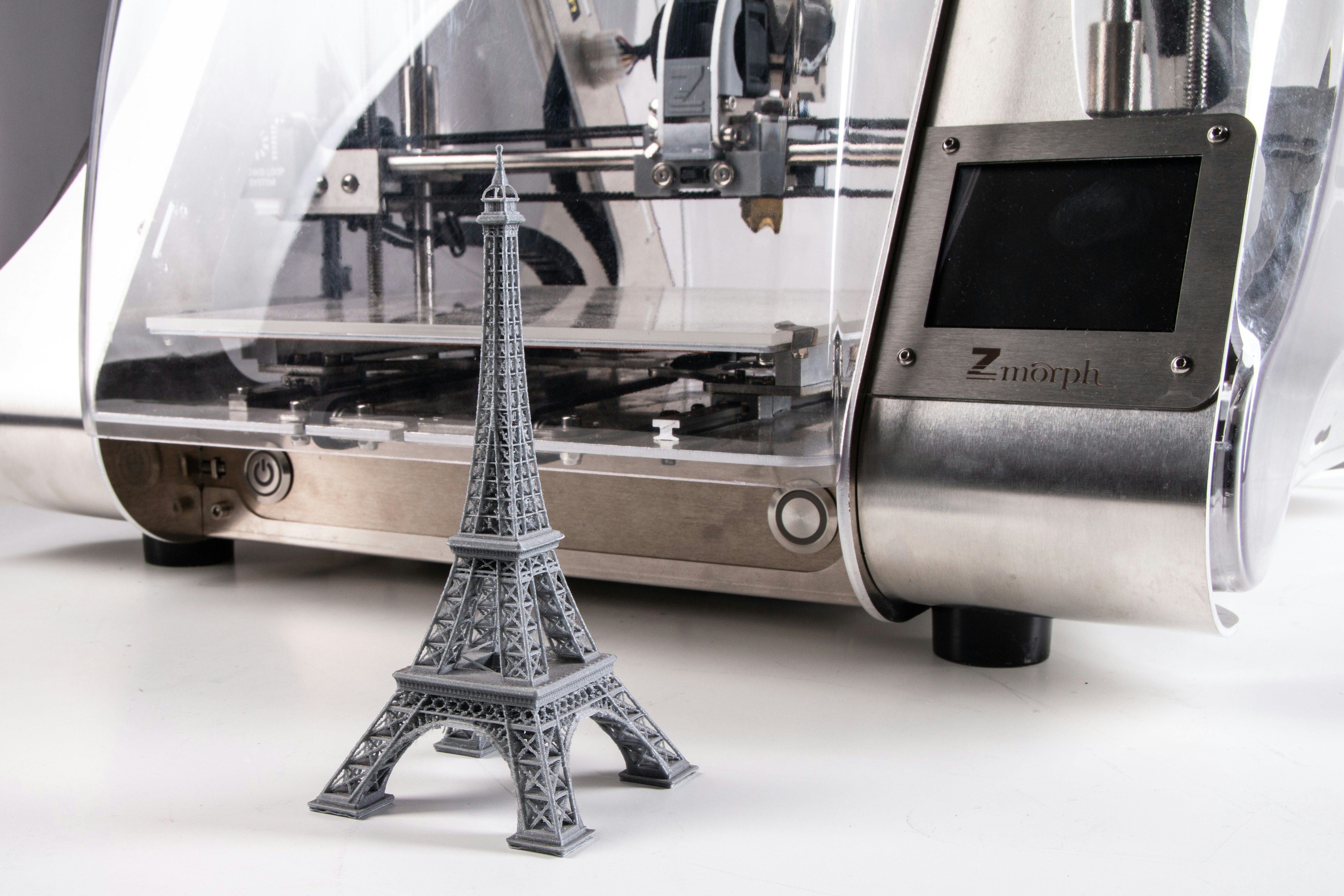

Starting with FDM printing, this technology employs thermoplastic filaments, which are heated and extruded through a nozzle to build three-dimensional objects layer by layer. The process begins when a digital model is sliced into horizontal layers, after which the printer deposits the thermoplastic filament in precise locations. The material cools and solidifies quickly, enabling the successful stacking of layers to produce complex geometries. Common materials used in FDM include PLA, ABS, and PETG, each contributing to specific strength, flexibility, and appearance attributes of the final printed object.

On the other hand, resin printing, particularly through a method known as Stereolithography (SLA), leverages liquid photopolymers that cure when exposed to ultraviolet light. This process allows for high-resolution prints, as the liquid resin is selectively solidified layer by layer based on digital instructions. The precision of resin printing makes it particularly appealing for miniatures, where fine details play a crucial role. Typical resins might include standard, tough, or flexible options, catering to various needs and applications.

While both technologies aim to convert digital designs into tangible objects, their methodologies differ significantly. FDM printers are typically more accessible and cost-effective, perfect for prototyping, whereas resin printers excel in detail and surface finish. Ultimately, the choice between resin and FDM printing will depend on the specific requirements of the project, especially in terms of detail and durability for miniatures.

Strengths of Resin Printing for Miniatures

When it comes to creating detailed miniatures, resin printing emerges as a formidable option, offering a range of strengths that set it apart from traditional FDM (Fused Deposition Modeling) methods. One of the primary advantages of resin printing is its exceptional ability to capture intricate details. The resolution of resin printers typically exceeds that of FDM printers, allowing for the production of miniatures that feature fine textures, sharp edges, and complex geometries. This capability is particularly beneficial for enthusiasts and professionals who demand an unrivaled level of precision in their miniature artwork.

In addition to detail, resin prints are known for their smooth finish. Unlike FDM prints, which may exhibit visible layer lines due to the extrusion process, resin prints are often smoother and more polished, resulting in a more visually appealing final product. This attribute is particularly important for miniatures, as it enhances the overall aesthetics, making them more appealing for display or gaming purposes.

The versatility in design offered by resin printing is another notable benefit. Complex shapes and intricate designs, which may pose challenges for FDM printers, can be tackled with relative ease using resin printing technology. Furthermore, the flexibility in scaling and print size allows creators to produce miniatures of various dimensions, ranging from small figurines to larger models, without sacrificing detail.

While resin printers may have longer print times compared to their FDM counterparts, the trade-off often results in a superior quality output that justifies the wait. The material properties of resin, including its durability and ability to withstand wear, further contribute to its popularity among miniature creators. As a result, those exploring options for miniatures frequently find resin printing to be a compelling choice that delivers high-quality results.

Advantages of FDM Printing for 3D Models

Fused Deposition Modeling (FDM) printing is renowned for its numerous advantages, particularly when it comes to creating miniatures and 3D models. One of the most compelling benefits of FDM technology is its cost-effectiveness. FDM printers tend to have a lower initial investment compared to resin printers, making them accessible for hobbyists and professionals alike. The cost of FDM filament is generally lower than that of resin, which further enhances its appeal for those producing a large volume of models.

Another significant advantage of FDM printing lies in its user-friendly nature. Many FDM printers come equipped with intuitive interfaces and software that simplify the printing process. This ease of use is beneficial for beginners who may feel overwhelmed by the complexities of more advanced technologies. Furthermore, the maintenance of FDM printers is typically straightforward, as they usually require less frequent cleaning and handling than resin printers, which demand more careful handling of materials and post-processing tasks.

The range of materials available for FDM printing adds to its versatility. Users can choose from various filament types, including PLA, ABS, PETG, and others, each offering distinct properties suitable for different applications. This extensive variety allows for customization, balancing performance and aesthetics, particularly vital for creating detailed miniatures. Additionally, FDM printing excels in producing larger models, with many printers capable of accommodating substantial build sizes.

Durability is another strong point of FDM-printed models. Items produced using FDM technology often exhibit robust structural integrity and withstand wear and tear better than their resin counterparts. This durability makes FDM a preferred option for functional prototypes, educational tools, or miniatures that require longevity. In conclusion, FDM printing provides a compelling set of advantages for creating miniatures, allowing for an efficient, user-friendly, and versatile 3D printing experience.

Making the Right Choice for Your Project

When deciding between resin and FDM printing for miniatures, several key factors should guide your choice, including print quality, cost, usability, and intended outcomes. Each printing method offers distinct advantages and may suit different project requirements. Resin printing, known for producing high-resolution miniatures with intricate detailing, is ideal for projects where the appearance and precision of the final product are paramount. However, this comes at a higher cost, both for the printer and the materials, which can be a drawback for budget-conscious creators.

On the other hand, FDM printing tends to be more economical, offering reasonable printing quality while allowing for larger projects and quicker production times. For hobbyists and professionals who prioritize scale and affordability, FDM can be an excellent choice. It is worth noting that FDM does not typically achieve the same elaborate level of detail as resin, which could be a deciding factor for those seeking finely detailed miniatures.

Before making your final selection, consider the availability of suitable STL files for your project. Certain designs are optimized for resin printing due to their detailed features, while other models lend themselves better to the FDM process. Analyzing your project goals can help in determining which STL files to select; they should be compatible with your chosen printing method.

Another practical suggestion is to conduct a small-scale trial print. This may involve testing specific designs and settings to assess detail versus cost before committing to a larger production run. Real-world examples show many creators successfully using both methods, with some blending the strengths of both – utilizing resin for detailed components and FDM for the larger structural pieces. By taking these factors into account, you can make a well-informed decision that aligns with your project aspirations and budget constraints.